The process of manufacturing FRP tubes

Introduction

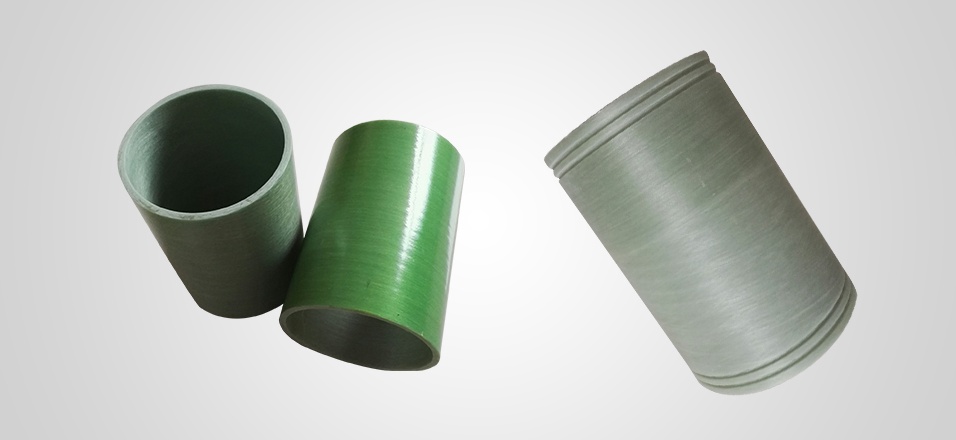

(Fiber reinforced plastic), or FRP, tubes are composite materials made up of a polymer matrix and reinforcing fibers such as glass, carbon, or basalt. They are commonly used in a variety of industrial applications for their exceptional strength, durability, and ability to withstand harsh environmental conditions. In this article, We will explore the manufacturing process of FRP tubes, the materials and equipment required, quality control measures involved, and applications of FRP tubes in different industries.

Materials and Equipment

The raw materials used in FRP tube manufacturing include resin, fiber reinforcement, and any additives such as pigments or fillers. The resin is usually a polyester or epoxy polymer that serves as the matrix for the reinforcing fibers. The fiber reinforcement can be made of glass, carbon, or basalt, and is used to add strength to the composite material. Additives such as pigments or fillers can be used to increase or modify the material's properties.

Manufacturing equipment includes a resin mixer, winding machine, and curing oven. The resin mixer is used to mix the resin with any additives, and the winding machine is used to wrap the reinforcing fibers around a mandrel or core. The curing oven is used to cure the composite material and set it into its final shape.

Manufacturing Process

The manufacturing process for FRP tubes is a multi-step process that involves the following stages:

1. Preparation of raw materials: The first step involves preparing the raw materials for fabrication. The resin is mixed with any additives using a resin mixer, and the reinforcing fibers are cut to the appropriate length and loaded onto the winding machine.

2. Resin mixing and application: The resin and any additives are mixed together to form a homogeneous mixture, which is then applied to the reinforcing fibers as they are wound around a mandrel or core.

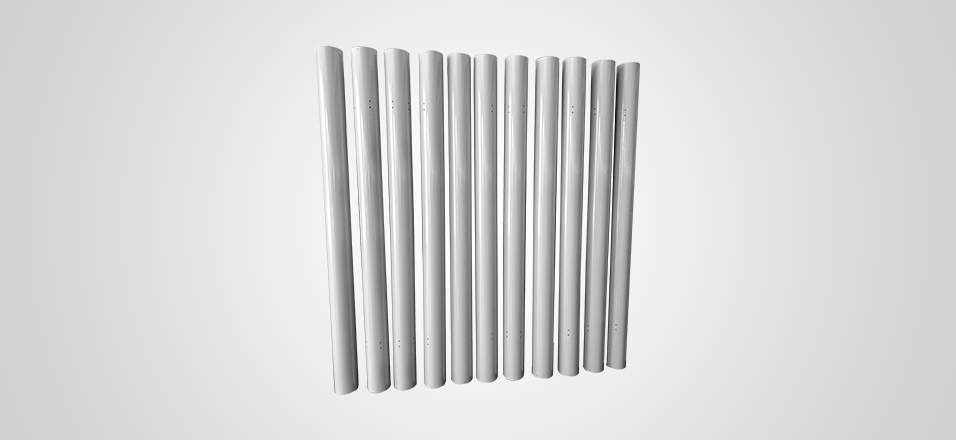

3. Fabric winding: The reinforcing fibers are wound around a mandrel or core in a specific pattern to create the desired shape and strength of the tube. Different winding patterns can be used to create different strengths and stiffness.

4. Curing process: Once the fabric is wrapped around the mandrel or core, it is loaded into a curing oven where heat is applied to cure the composite material. The curing process is usually controlled to ensure that the composite material sets at the correct temperature and for the correct amount of time.

5. Cutting and finishing: After the composite material has been cured, it is removed from the mandrel or core and cut to the desired length. The tube is then finished by grinding, sanding or polishing to achieve the desired surface finish.

Quality Control Measures

Quality control measures are essential to ensure the reliability and performance of FRP tubes. The following measures are taken to ensure the quality of FRP tubes:

1. Inspection and testing of raw materials: The raw materials are inspected and tested to ensure that they meet the required quality standards, such as the strength and stiffness of the fibers and the chemical composition of the resin.

2. Quality checks during fabrication: Quality checks are conducted during the manufacturing process to ensure that the composite materials are manufactured according to the required specifications. This includes checking the curing temperature and time, the winding pattern, and the thickness of the composite material.

3. Testing and validation of finished FRP tubes: The finished FRP tubes are tested and validated to ensure that they meet the required standards for strength, stiffness, and other performance criteria. This includes testing for compression, bending, torsion, and shear strength, as well as other properties such as thermal and fatigue resistance.

Applications of FRP Tubes

FRP tubes are used in several industrial applications because of their strength, light weight, and durability. Some common uses of FRP tubes include the following:

1. Oil and gas industry: FRP tubes are used in the oil and gas industry in pipes, tanks, and other equipment because of their excellent resistance to corrosion caused by crude oil, seawater, and other corrosive materials.

2. Infrastructure and construction: FRP tubes are used in bridges, buildings, and other infrastructure projects because of their high strength-to-weight ratio, durability, and resistance to weathering.

3. Renewable energy sector: FRP tubes are used in wind turbine blades, hydroelectric power plants, and other renewable energy applications because of their exceptional strength, durability, and ability to withstand harsh environmental conditions.

Advantages of FRP Tubes

FRP tubes have several advantages over traditional materials such as steel, aluminum, and concrete. Some of the advantages include:

1. Lightweight and durable: FRP tubes are lighter than steel and concrete, making them more convenient to transport, install and maintain. Additionally, FRP tubes are durable, and they can last for several years before needing to be replaced.

2. Corrosion resistant: FRP tubes are highly resistant to corrosion, making them ideal for use in harsh environments that are characterized by harsh chemicals, saltwater, and humidity.

3. Low maintenance: FRP tubes require less maintenance than traditional materials such as steel, concrete or aluminum. Repairs can be done easily without the need for specialized equipment or tools.

Conclusion

In conclusion, the manufacturing process of FRP tubes involves preparing the raw materials, mixing the resin, winding the reinforcing fibers around a mandrel, curing the composite material, and finishing the tube. Quality control measures are also essential to ensure the reliability and performance of FRP tubes. FRP tubes have several advantages over traditional materials such as steel, including their light weight, durability, and resistance to corrosion. With these advantages and their versatile applications, it's clear that the future for FRP tubes is bright.